Smart Maintenance for Uninterrupted Operation in the Energy Sector

Sudden failures in power generation facilities can lead to operational losses and high maintenance costs. Renewasoft’s predictive maintenance solutions ensure uninterrupted production and operational efficiency by detecting equipment failures in advance with SCADA data, IoT sensors and machine learning algorithms.

Predictive Maintenance Solutions

📡 Real Time Monitoring with SCADA and IoT Sensors

With the data received from SCADA systems and IoT-based smart sensors, we instantly monitor all equipment and detect possible malfunctions. We continuously analyze the health of critical equipment with vibration, temperature, pressure and acoustic sensors. With remote access and cloud-based data analysis, plant managers can get information about maintenance status from anywhere.

📊 Anomaly Detection with Machine Learning

We develop intelligent models that identify deviations in equipment performance by analyzing historical maintenance data. We predict failures that may occur in critical components with anomaly detection algorithms. By performing predictive maintenance planning, we make planned maintenance processes more efficient.

🔍 Failure Prediction and Preventive Maintenance Recommendations

We calculate the probability of failure of critical equipment in power plants with SCADA data and big data analytics. We extend equipment life and reduce unnecessary maintenance costs with low-cost maintenance strategies. We enable maintenance teams to make more informed decisions with real-time health analysis.

⚙️ Optimized Predictive Maintenance for Power Plants

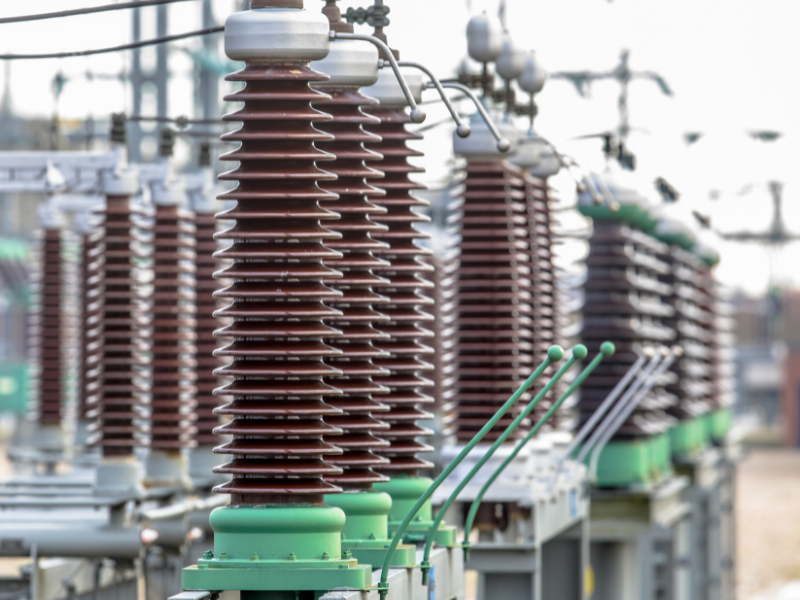

We offer customized maintenance solutions for turbines, generators and switchgear in hydroelectric power plants. We develop predictive maintenance algorithms for pumping stations, transmission lines and transformers. By establishing integrated systems with industry stakeholders such as EPİAŞ and DSİ, we ensure reliable and efficient power supply to the energy market.

🌱 More Sustainable and Efficient Energy Production

We increase operational efficiency with fewer unplanned downtime and higher equipment lifetime. Thanks to predictive maintenance supported by artificial intelligence, we ensure lower carbon emissions and energy production processes that minimize environmental impacts. With the efficient maintenance strategies offered by our systems, we ensure less material consumption and lower maintenance costs.

🔍 Why Renewasoft Predictive Maintenance Solutions?

- Real-Time Monitoring: Monitor equipment health 24/7 with SCADA and IoT sensors.

- Predictive Planning: Optimize maintenance processes by predicting failures in advance.

- Cost Advantage: Reduce maintenance costs by reducing unnecessary downtime.

- High Efficiency: Increase the efficiency of your power generation plants by extending equipment lifetime.

- Sustainable Energy Generation: We offer lower carbon emissions and maintenance solutions that minimize environmental impact.